To consider an application for financing, fill out the form and send it to us by e-mail along with the project brief, or contact our experts

Due to the growing need to reduce the cost of gas transportation, the business is looking for new solutions such as the use of CNG (compressed natural gas) and LNG (liquefied natural gas).

Due to the fact that natural gas after liquefaction takes up less space, its transportation, especially over long distances, is more profitable (1 m³ of LNG corresponds to 600 m³ of gas).

The liquefaction of natural gas and its transportation by tanker has been used commercially for over 40 years. This practice requires infrastructure expansion, which includes the construction of new LNG plants as well as LNG terminals and LNG carriers.

Despite the complexity and high cost of high-tech infrastructure, in recent years there has been an increase in the share of LNG in total natural gas sales in the world.

This is mainly due to accelerating technological progress and reducing the cost of liquefaction, transportation and regasification thanks to innovative solutions.

Currently, the largest quantities of liquefied natural gas are produced in the United States, Southeast Asia, the Gulf region and North Africa. A significant share of global LNG demand is concentrated in Japan, South Korea, France, Spain and other EU countries. In Europe, the share of LNG will continue to grow due to the depletion of gas fields and close proximity to LNG producers.

The engineering design of liquefied natural gas plants and the construction of new facilities is in growing demand in regions that are actively producing gas and are looking for wider markets without building gas pipelines.

The list of LNG producers already numbers about 20 countries and is expanding.

Experts predict that the share of LNG in global gas exports will increase to 60% by 2040, so the interest of leading companies in this area is obvious. Today, the world is facing a gas revolution, and advanced technologies can play an important role in providing a competitive edge to the most flexible producers.

In the early 2000s, the capacity of LNG plants rarely exceeded 5 million tons per year, but today companies around the world are implementing fantastic multi-billion dollar projects, many times exceeding the capabilities of their predecessors. For example, a 32 million tonnes per year plant under construction in Qatar will soon expand the capacity of the Northern Field to nearly 100 million tonnes per year.

The cost of this project reaches $ 32 billion.

LBFL's team offers a full range of professional services related to the design of LNG plants anywhere in the world.

Together with our partners, we are ready to act as your responsible EPC contractor and provide project financing on attractive terms.

LNG plant working principle

Today natural gas is the most important gas energy source, the role of which is constantly growing.The main component of natural gas is methane, which in natural conditions is always accompanied by higher molecular weight gaseous (ethane, propane, butane) and liquid hydrocarbons.

Natural gas mixes easily with other gaseous components including carbon monoxide and carbon dioxide, hydrogen sulfide, nitrogen, hydrogen, helium, and argon. Dry natural gas is obtained from independent fields, while wet natural gas is extracted from oil fields or condensate fields that are rich in higher liquid hydrocarbons. Methane gases are also accompanying coal deposits.

The composition of natural gas from various sources can vary significantly; therefore, the technology for its purification and liquefaction must be adapted to the composition of the field being developed. Depending on the composition of the source gas and the purpose of LNG, natural gas processing can be aimed at purifying it from carbon dioxide, hydrogen sulfide, water and other impurities. LNG plants carry out the separation of heavy hydrocarbons, denitrification and recovery of helium by various technical methods.

Since liquefied natural gas has a volume of about 600 times less than the volume of gas under normal conditions, this allows it to be transported without a pipeline network by sea and land transport.

Liquefied natural gas has an energy density of about 55 TJ / ton, which is 31% higher than the specific energy of crude oil (about 41.9 TJ / ton).

The liquefaction process requires large investments and consumes a significant amount of energy, therefore this method is chosen when the distance to consumers is too great for its transportation via an onshore gas pipeline, or when the characteristics of the land, gas pipeline and external factors interfere with an adequate supply of natural gas in the traditional way.

Natural gas can also be liquefied to store surplus near the consumer.

LNG plants built close to the field are usually highly efficient and do not require expensive infrastructure.

Natural gas preparation and liquefaction processes

The first link in the LNG chain is a gas liquefaction plant. Before condensation begins, the gas is dried and carbon dioxide and other impurities are removed.Liquefaction of natural gas is achieved by lowering its temperature to -162C.

Depending on the required capacity of the plant, the composition of the source gas and its pressure, a suitable type of equipment is selected.

Before being liquefied, natural gas must go through a series of processes to remove heavy hydrocarbons and impurities that have not been removed after leaving the well. Gas is usually supplied to the plant at normal temperature, which usually corresponds to the temperature of the gas pipeline, at a pressure that depends on the operating conditions of the gas network.

The gas liquefaction cycle operates at a pressure of about 50-70 bar, so in many cases it is necessary to increase the pressure with special compressor equipment to ensure an efficient and continuous process. An important role in the technological process belongs to high-tech filters and other systems for effective cleaning and separation of valuable components, which can be stored and used in the future.

There are various LNG production concepts currently on the market, but they are all based on cooling natural gas to a temperature at which the gas becomes liquid at atmospheric pressure.

The main solutions for the engineering design of LNG plants are the classic cascade cycle, mixed refrigerant cycle and gas depressurization with a turboexpander. After liquefaction, the gas is stored in special tanks, from where LNG carriers (so-called methane carriers) are loaded.

Separate stages, equipment and technologies for pretreatment and liquefaction of natural gas will be briefly described in the following sections of the article for informational purposes.

The LBFL team is ready to advise you on any technical and financial issues related to the construction of a liquefied natural gas plant.

Contact us to find out more about our proposals for your project.

LNG plant engineering design basics

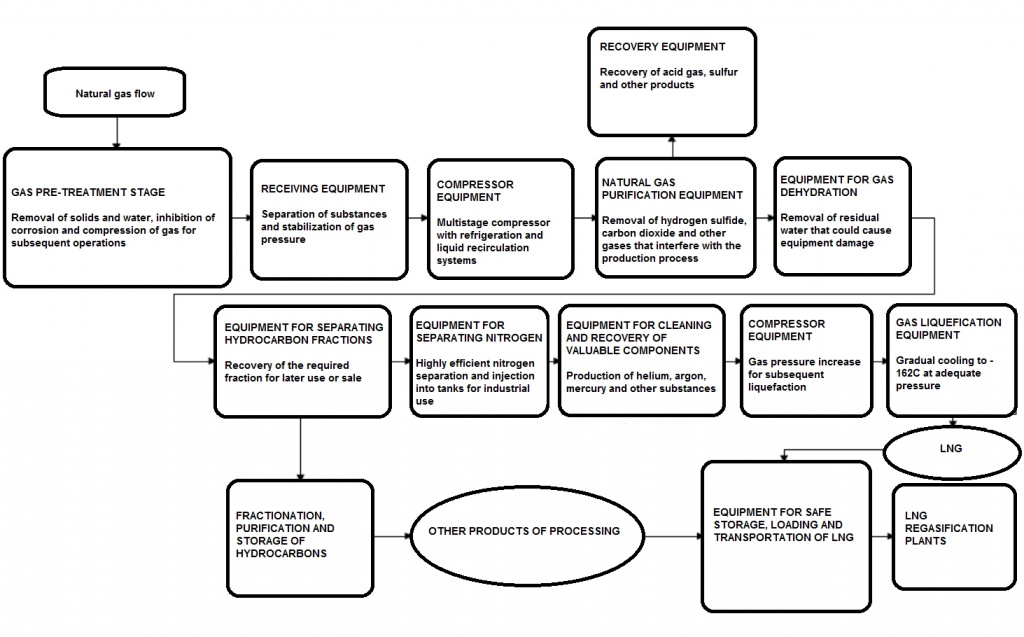

Liquefied natural gas plants are unique projects, each of which is designed according to individual requirements, depending on the characteristics of the gas and the client's requests for the yield and quality of finished products.The figure below is a block diagram showing the stages of natural gas processing at an LNG plant. This is a general overview of the steps to maximize gas utilization from well exit to liquefaction. Each of them represents a separate processing stage with appropriate technologies that are developed and implemented in accordance with the desired products.

Figure: Components and operation of the LNG plant and associated infrastructure.

During the engineering design of an LNG plant, engineering team is faced with numerous challenges such as finding and implementing optimal technologies to remove certain impurities.

Each stage of the technological process, from the removal of impurities to fractionation, presents a unique challenge that requires deep professional knowledge, practical experience and widespread use of modern technologies and equipment.

Extraction and pre-treatment of gas

Downhole operations involve the first contact of the equipment with gas after it exits the well, passing through the surface of the earth through the pipe.A system of valves and connections is installed at the wellhead, distributed through pipes of different sizes, designed to change the pressure and flow in such a way as to ensure the correct operation of the equipment. This process is strictly controlled by pressure measuring instruments that transmit recorded information to the control room.

The gas passes directly to a three-phase separator capable of handling hydrocarbons, water and gas. This equipment is called "knock-out drums" because at its inlet there is a diverging element that sharply collides with the gas, separating the flow and the components that this flow entrains. In this case, there should be condensate storage tanks at the wellhead, from where the hydrocarbons go to the LNG plant.

All LNG plants carry out initial gas cleaning operations that remove liquid hydrocarbons and particulate matter that may have been carried away from the well.

Also, preliminary removal of liquid and prevention of hydrate formation, removal of acid gases (CO2 and H2S), compression and pressure stabilization are carried out.

The so-called two-phase separators (scrubbers) effectively separate gas from liquids that it may contain in wells with stable gas cushions. Separation is very important if the produced natural gas carries a significant percentage of heavy hydrocarbons and water, as in the case of associated gas.

Natural gas entering the LNG plant loses pressure during transportation due to power loss, gas expansion and cooling, so that different vapor fractions will condense, carrying impurities with them. Consequently, a slug-catcher and a particulate filter capable of retaining particles larger than 1 micron are required.

Subsequently, the gas pressure rises to values compatible with the thermodynamic transformations that the gas stream will undergo during the liquefaction process.

Typically, a cascade process requires about 45-50 bar, while a mixed refrigerant process requires even more pressure.

The separated water and solids are prepared for disposal or further processing, while the condensed hydrocarbons are sent to recovery or fractionation systems, depending on the process.

Gas pressure regulation

All LNG plants initially develop acceptable requirements for natural gas, which are used in the engineering design of equipment that is associated with the technological process.However, the chemical environment, temperature and pressure in the wells are extremely variable, which requires pretreatment of natural gas before processing it.

Compressor equipment, which regulates the pressure of natural gas supplied to the next stages of the technological process, is of great importance.

Accurate stabilization of gas pressure improves processing efficiency and protects equipment from possible breakdowns.

If high pressure technologies are to be used in the LNG plant, such as desulfurization and dewatering systems using contactors and molecular sieves, it is imperative to adapt the pressure at this point.

This is a cost-effective solution that allows for better separation of condensables at lower costs in the next stages of the process.

At this stage, special compressors are installed to work with very high pressure, but the engineers will adapt the specific parameters of the equipment to a particular process. Refrigeration systems are also often used to prevent mechanical damage to compressors due to high temperatures.

Dealing with high pressures, as in the case of a natural gas liquefaction system, requires strict design specifications as critical conditions are created in the process. In each case, the engineering team develops a customized set of equipment that allows the incoming gas to be adapted to the requirements of further stages of LNG production.

Natural gas purification

Natural gas from a well can contain components that adversely affect its quality and properties.Therefore, in the process of engineering design of LNG plants, it is necessary to carefully plan the stage of removal of acid gases (H2S, CO2, mercaptans).

Effective purification of the source gas allows further avoidance of equipment corrosion during gas processing and avoidance of deterioration in the quality of the finished product. Many LNG plants use acid gas removal processes, commonly referred to as sweetening, using absorption systems with aqueous solvents capable of retaining these compounds.

However, this is not an easy task as it is difficult to choose the most suitable solvent for processing.

Equipment for natural gas dehydration

In general, downhole conditions result in the saturation of natural gas with water vapor, but changes in conditions occurring during transition to the surface cause partial condensation of water.When natural gas passes through equipment, even small amounts of water can corrode pipes and severely damage compression systems and reduce heating value.

Residual water in natural gas during deep freezing can cause blockages due to particle settling in pipes, leading to equipment failure.

For this reason, engineers pay increased attention to the processes of dehydrating natural gas before entering the LNG production cycle.

An example of liquid removal equipment is a filter separator. This equipment usually consists of two compartments. The first compartment contains a filter medium in which heavy water droplets are collected and separated as the natural gas passes. The particles are transferred to a second compartment which contains a mist eliminator that collects water and directs it to a storage tank. Thus, the gas is cleaned of liquids that can potentially cause problems in the equipment.

To effectively remove water, advanced technologies can be used, some of which are based on separation in solutions and others based on adsorption in a stationary phase.

Separation and recovery of hydrocarbons

Depending on the composition of natural gas and the customer's requirements for the final products of processing, LNG plants implement various methods of separating liquid products at the stage of initial purification, compression and fractionation.

There are various ways to use the resulting products. In many cases, complete recovery of each component is carried out, which means strict separation of each of the hydrocarbons present (eg ethane, propane, isobutane). Since liquefied natural gas is 98% methane and contains no more than 2% of other light hydrocarbons, the process of its production is associated with technical difficulties.

There are different ways of cleaning gases from condensed and solid liquids.

The equipment used for this purpose is called separators, and their operation is solely related to the type of impurities and the composition of the gas.

Separation equipment must not only handle liquid and gaseous phases, but also effectively separate immiscible liquid phases such as water and hydrocarbons.

Nitrogen re-injection

A common practice in secondary hydrocarbon production is inert gas injection, which does not degrade the quality of the recoverable hydrocarbons, but ensures that sufficient pressure is maintained in the well.One of the inorganic components high in natural gas is nitrogen, which must be removed to produce higher quality fuels that meet international standards.

For this reason, engineers are using special equipment to extract and re-inject nitrogen recovered from natural gas, which is an adequate solution for the operation of wells.

A variety of technologies exist for separating nitrogen from natural gas, ranging from cryogenic separation to molecular sieve adsorption. Their use depends on the characteristics of the feed gas, the cost of the technological processes and the purpose of the separated gas.

Extraction of components with low content

According to the characteristics of the fields, natural gas may contain some substances in very low proportions compared to hydrocarbons or sour gases.When designing equipment for the recovery of low grade components, it is important to consider two main factors.

First, the choice of equipment should ensure the minimum cost of production. Funds should be invested in robust processes and equipment to recover high-value components that may be more costly to produce from other sources or because there is no other available source. This applies to products such as helium, argon, benzene, toluene, ethylbenzene and xylene.

A second factor to consider by engineers is potential operational problems caused by plugging of high pressure equipment such as molecular sieves. In addition, harmful substances in natural gas can cause long-term health problems for consumers and environmental pollution.

Therefore, LNG plants must effectively remove impurities of mercury, arsenic and radon (radioactive material).

Natural gas compression equipment

After natural gas has been processed to remove impurities to meet quality standards, it is sent to high-capacity compressors to be compressed and fed to a liquefaction line to produce LNG.Most LNG plants using cryogenic systems install turbo expanders, where a sudden decrease in pressure cools the gas and uses the energy from the expansion in the compressors of the same process.

When designing equipment for this technology, it is important to calculate the compression ratio, since errors at this stage, depending on the material of construction, can lead to equipment damage and require expensive repairs.

Liquefaction of natural gas

LNG is produced from natural gas in a multi-stage liquefaction process.Condensation is the phenomenon of a change in the state of aggregation, the transition of a substance from a gas phase to a liquid. This can occur at normal pressure and below critical ambient temperature. Gas condensation is associated with a decrease in the distance between the molecules of its components. The drop in temperature causes the particles to move slowly, and the forces of interaction between them increase sharply until a new state of equilibrium is reached.

Condensation processes can proceed in different ways when there are impurities in the gas.

The main component of natural gas is methane.

Besides it, natural gas contains ethane, propane and heavier hydrocarbons, as well as nitrogen, oxygen, carbon dioxide, and sulfur. In the liquefaction process, natural gas must be thoroughly cleaned, mainly of water and carbon dioxide, in order to prevent the formation of solid particles during cooling. The result is liquefied natural gas, a very pure gas made up of 98% methane and 2% impurities.

The easiest way to liquefy natural gas is in single-stage Joule-Thomson or Brighton chillers.

The working medium of the chillers can be methane or nitrogen. Natural gas passes through a heat exchanger, where it is cooled in contact with the environment.

The heat exchanger serves as the main element of the gas condenser. The disadvantage of such a system is the high temperature difference between the evaporating methane or nitrogen and the cooled natural gas, which predetermines the relatively low thermodynamic efficiency of the process.

Natural gas can be liquefied in cascade systems using three pure refrigerants (propane, ethylene and propane).

In such systems, cooling energy is generated at three temperature levels and the temperature difference in each stage is much less than in the case of a single stage system.

Further efficiency gains can be achieved by replacing pure gases with mixtures selected so that the temperature difference between the LNG and the evaporating refrigerants does not exceed a few degrees Kelvin at any point in the heat exchanger. Three-stage mixing and expansion systems are today considered the most thermodynamically efficient natural gas liquefaction systems.

Table: Some of the liquefaction methods used in LNG plants.

| Method | Short description, advantages and disadvantages |

| Classic cascade cycle | Purified from carbon dioxide and water, natural gas is pressurized and cooled in three refrigeration cycles, in which the refrigerants are propane, ethane and methane. The propane from the first cycle is used simultaneously to liquefy ethane from the second cycle and ethane from the second cycle is used to cool the methane in the third cycle. The advantage of this method is its high energy efficiency. The disadvantage is a large number of equipment for the process, as well as a high demand for pure ethane and propane. |

| Mixed refrigerant cascade cycle | This is a modification of the classic cascade LNG production cycle using only one compressor and one refrigerant, which is a mixture of hydrocarbons. Natural gas is first cooled using a propane refrigeration cycle and then cooled with a hydrocarbon mixture. This method is more energy intensive than the classic cascade cycle, but has the advantage of fewer installations. Due to the lower operating costs, the method is in high demand. |

| Decompression cycle with turbo expander | Equipment for natural gas liquefaction with turbo expanders works on a principle similar to the classic Joule and Thompson method. In this process, a portion of the gas is expanded in a device called a turbo expander and then cooled to a very low temperature. Subsequently, the cooled gas is used to condense the rest of the gas flowing through the unit. This method is relatively simple and requires little investment. However, the decompression cycle consumes a lot of energy, which is needed to compress the gas. For this reason, the method is used by LNG plants with access to cheap energy. |

There are several liquefaction technologies in the industry.

The most widely used are Air Products and ConocoPhillips Optimized Cascade and their modifications. In addition to the above, there are numerous technologies for the production of LNG, adapted to specific conditions. For example, the well-known AP-C3MR technology is most applicable to hot countries. In general, natural gas liquefaction technologies are developing rapidly, becoming cheaper and more efficient.

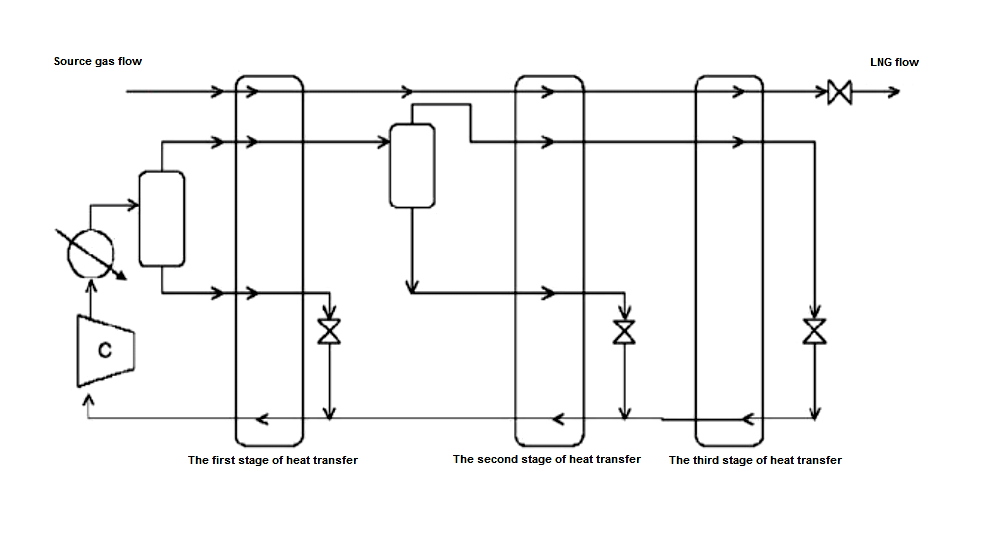

The general scheme of the gas liquefaction plant is shown in the figure below.

To address adaptability issues, sometimes the initial investment needs to be increased to provide higher plant capacity and improved energy efficiency. In other words, large liquefied natural gas plants require relatively large investments, which producers justify by reducing the cost of production per unit volume of gas.

To improve energy efficiency, self-cooling / condensing cycles are often used, which require high refrigerant circulation rates.

Due to the high energy consumption in gas refrigeration processes, engineering teams are constantly looking for alternatives that increase the energy efficiency and competitiveness of new LNG plants.

The selection of a thermodynamic cycle is a fundamental step in process design as it represents, together with the purchase of feed gas, about 75% of LNG production costs.

Recovery of other valuable substances

Typically, natural gas provides fuel, refrigerants and valuable components in small proportions, however, intermediate stages of gas processing also recover components that can reduce the quality of the main products or cause problems in the operation of the plant.These components are mainly acid gases (H2S, CO2, mercaptans) that cannot be released into the atmosphere for various reasons, including environmental legislation, good manufacturing practices and the high cost of equipment used to remove them.

In accordance with the amount of these compounds and their relative proportion in natural gas, they should be considered as raw materials for the production of additional chemical products.

The LNG plant engineering team can provide a variety of solutions to improve the ROI through these processes.

LNG plants extract valuable chemicals from the process of removing sulfur, CO2 and other substances, supplying recovered compounds to chemical plants. Later, this chemical raw material is used for the production of sulfuric acid, urea, and carbamide.

LNG storage and transportation

Storage and transportation of liquefied natural gas to end users are important stages of the plant's operation, requiring close attention of engineers.Moreover, LNG storage tanks in some projects account for up to 30% of the total project cost, due to strict safety standards and requirements for design, materials and methods of joining elements.

Transportation of LNG by sea is one of the most cost-effective services for the gas industry because the appropriate equipment and ships enable companies to transport gas safely over long distances in a relatively short time frame. However, other alternatives are being proposed today, such as transportation by land using special tanks. This route is widely used to transport gas between service and distribution stations.

The choice of methods for storing and transporting products is closely related to other issues of engineering design of the future facility, therefore it should be addressed in an integrated manner within the framework of a common project.

Engineering design of auxiliary equipment and systems

All stages of natural gas processing will require the construction and installation of a set of auxiliary equipment, control systems and computerized tools.This aspect is related to the development of contingency plans and rules for safe gas handling, continuous remote monitoring and control.

The practical implementation of an investment project of this scale implies a huge responsibility of an engineering company for every detail, which must strictly comply with technical specifications and safety standards.

Liquefaction of natural gas is one of the most complex and critical operations in the context of industrial safety, since flammable components are processed at every stage, and any errors in equipment design must be excluded at the engineering design stage.

Ancillary equipment for LNG plants

A liquefied natural gas plant can be compared to a large city, consisting of hundreds of technical elements, dozens of departments and numerous services.For continuous operation, the giant complex must receive electricity, cooling water and high-temperature fluids for heat exchange. Ventilation systems, liquid collection and processing equipment, water treatment systems and other critical components are monitored around the clock by dispatchers and smart systems.

Most LNG plants use turbo-expander equipment to generate some of the electricity they consume. Other power generation systems, such as cogeneration systems, can significantly reduce costs.

Heat transfer fluids, such as steam or thermal oils, are mainly required in solvent recovery systems, so their consumption is low in this class of plants compared to the consumption of thermal energy in an oil refinery. Cooling water is used in heat exchange systems, condensers and compressors.

A continuous supply of clean, dry air is critical to the operation of the plant due to the large number of pressure control valves. This type of facility uses standby compressors.

Another common system is nitrogen purge lines, which are used to compensate for pressure in equipment.

LNG production control systems

LNG plant control operations are considered to be the most important auxiliary processes that ensure optimal operating conditions and maintain the required performance for all media and products.

The engineering team develops individual digital control systems (DCS) for each piece of equipment, registering variables and sending signals to actuators that will move valves, activate pumps, or perform other action. Today there is a tendency to integrate all installations under a single computerized system, which increases the quality and safety of the technological process as a whole.

There are also sophisticated mechanisms such as Advanced Management Processes (APCs) that integrate existing DCSs and provide a clear structuring of the management process. APC uses multi-parameter mechanisms that are described by a process and optimize each operation by making changes to several execution algorithms.

LNG plants make extensive use of SCADA (Supervised Control and Data Acquisition) systems, which monitor the operation of wells, allowing, for example, to control gas dehydration and sulfur removal plants.

These systems can be connected to a variety of sensors, including indirect composition sensors that use valves as the final control element.

Typically, such a system has a series of distributed pressure, temperature and flow sensors combined with reliable instruments that allow composition analysis (chromatography, infrared, mass spectrometric sensors) and gas component determination.

All this is tied to the central operating system, which sends signals to the actuators.

Safety measures

LNG plant safety systems integrate all those plans, devices, equipment and / or processes that are aimed at improving the lives of people in nearby communities and workers, as well as ensuring the integrity of equipment, minimizing the costs associated with failures, accidents and any hazardous situation.Liquefied natural gas plants must include emergency shutdown and valve closure systems to avoid gas leaks in process equipment, ventilation and vapor recovery systems. Boilers or combustion systems must be designed to burn at least 80% of the gas being handled, as this is the last option in the event of a plant emergency.

Safety devices include sealing valves, antistatic systems and electrical equipment protection, bursting discs, fire traps, fire protection systems, flood protection systems, seismic resistant equipment, etc.

Typically, all equipment in an LNG plant must be designed for the extremely high pressure and temperature conditions it maintains, in addition to the safety margins for filling and storing gas.

All measures that are taken into account by engineering teams when designing safety systems must be designed for complete equipment failure. In addition, engineers consider existing relationships with other equipment by developing failure safety matrices and procedures that allow operators to act in the right way to resolve the problem.

Our services for the gas industry

Costex Corporation DBA, an international company, is ready to support major projects in the gas industry.We offer:

• Project finance for LNG plants

• Engineering design of various types of LNG plants.

• Construction of oil and gas infrastructure facilities under the EPC contract.

• Operation and maintenance of LNG plants and other facilities.

• Modernization of oil and gas enterprises.

Our company offers financing for the construction of liquefied natural gas plants on flexible terms.

LBFL provides project finance and long-term bank lending for large projects.

We actively cooperate with partners in Europe, USA, Latin America, North Africa, the Middle East and East Asia, using advanced technologies and financial instruments to solve clients' problems.

Contact our representatives at any time to find out more.