Project finance and lending of automotive plants

Costex Corporation DBA offers:

• Project financing from $ /€ 5 million or equivalent and more

• Minimizing the contribution of the project promoter

• Investment loan term up to 20 years

• Credit guarantees

Volkswagen, Toyota, Renault-Nissan, Hyundai-Kia, General Motors, Ford and Honda remain the leaders of the global automotive industry, largely determining the economic and technical trends in the development of the industry.

In many manufacturing countries, the automotive industry is considered a strategic economic pillar due to the various benefits it brings to the creation of high-wage jobs, taxes and fees generated from commercial operations in the industry, staff training and the development of a dealer network.

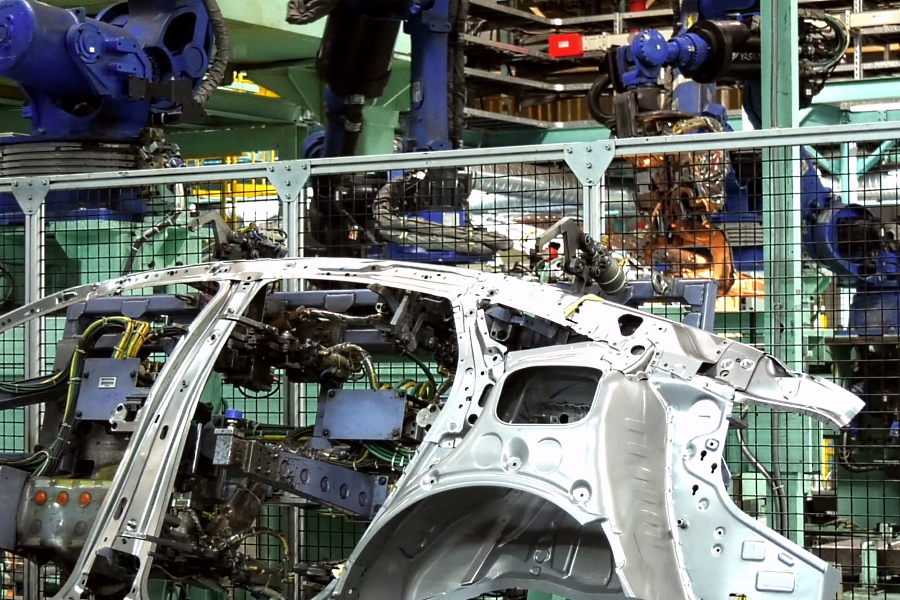

Funding for the construction and modernization of automotive plants is critical to this business in the face of globalization and increased competition in the global market.

The development and growth of the automotive industry is the result of a sequential chain of transformations that include the evolution of production capacity towards the globalization of the sector, as well as the implementation of a consistent and coherent industrial policy at the national level.

In combination with affordable funding sources, these factors stimulate the development of the automotive industry and related industries with high added value.

According to Deloitte, over the period 2018-2035, auto industry revenues will increase by 50% thanks to the sale of cars and parts, but during this time financial services in the auto industry will increase by 100%.

The automotive industry finance market has been valued at US $ 213 billion in 2020 and is expected to reach US $ 300 billion by 2026 (CAGR is about 6%).

Currently, the main financing sources are bank loans, leasing and project finance (PF) services for large enterprises such as automotive plants and dealers.

Costex Corporation DBA is ready to offer financing for the construction of automotive plants, as well as provide your company with a flexible long-term loan for automotive assembly facilities of 50 million euros or more.

The financial needs of automotive manufacturers in the context of modern trends in the development of the automotive industry in Europe and the world

Funding for automotive plants is closely related to general industry finance trends, and vice versa: everything that happens to the automotive industry changes the dominant economic models.This sector has always been characterized by strong impact on the rest of the sectors, advanced organizational and production models, and the ability to impose new economic trends and consumption habits.

The automotive industry is a vivid illustration of current industrial trends.

Every year we have seen an acceleration in the growth rates of the economies of regions with lower labor costs.

Together with the growing demand in emerging markets, this leads to a geographic expansion of the automotive sector and, consequently, to a shift of the spare parts industry towards these countries.

The world is experiencing revolutionary changes, supported by a shift in the economic axis towards the Asia-Pacific region, where a significant part of industrial production is in developing countries.

In the 2020s, the sector came under massive public pressure for automakers to move towards sustainable economies. This has already led to a crisis in the diesel car industry, which is being replaced by carbon neutral electric vehicles with their new technologies and trends.

Today, technology initiatives from Google, Apple and Tesla are rapidly changing the technological and economic landscape of the global automotive industry. The new reality suggests that the car should become the personification of environmental safety and unprecedented comfort for humans, supported by artificial intelligence and receiving the unique benefits of digital technology.

The proliferation of electric vehicles and autopilots, changing consumer preferences and market models impose tough technical and financial demands on automakers.

The costly modernization of factories is becoming the most important condition for survival in the new market.

New technologies and the choice of consumption model between buying and car sharing will have a powerful impact on the production of cars in the next few years. We are experiencing a revolution that accompanies profound social change, total digitalization, electrification, widespread adoption of nanomaterials and the transformation of the modern concept of user mobility and comfort.

The emergence of new financial models and the shift towards cooperation with related sectors (electrical equipment manufacturing, infrastructure construction, software development) require a comprehensive and highly professional approach to planning new investment projects.

Financing the construction of new automotive plants in such conditions will require a flexible approach that takes into account the novelty and immaturity of innovative technologies, large amounts of investments, long payback periods and high risks. Governments should not stand aside, helping private capital through PPP projects with the introduction of Industry 4.0 and the construction of smart cities.

A quick overview of the global automotive industry

Funding for the automotive industry has shifted to the East over the past 15 years.In 2007, a triad of leading car manufacturers (USA, European Union, Japan) shared 58% of the world market, but in 2017 they accounted for "only" 44%.

During this period of time in the world, China declared its leadership, producing at that time about 30% of the total number of cars in the world.

In general, investor interests are gradually moving towards Asia, where 55% of all global car sales were registered in 2017. This indicator has risen by 22 points over the previous 10 years, while the European market has fallen by 10 points.

The 2015 diesel engine crisis in the United States (dieselgate) accelerated the electrification of the automotive sector, including the approval of tough regulatory measures in several countries around the world. Prior to the pandemic, this sector maintained a constant positive trend, which will accelerate in the future.

The evolution of the automotive sector, the transfer of added value, the emergence of new promising players in developing countries and the increase in the impact of social factors create some additional difficulties for forecasting and planning investment projects in this area.

The rise in popularity of electric vehicles will not be the only technical solution, as different engine models will coexist in the medium term.

This is a critical fact on which all future automotive plants business models will be built.

Electronic safety systems, high quality semiconductors and composite materials are increasingly driving the success of an automotive project. Today, investors and lenders are demanding a more comprehensive business plan from automakers, including cooperation agreements between manufacturers of automotive components that have become prominent players in the market.

In recent years, the German Bosch has been the leader in the ranking of component manufacturers, followed by the Japanese Denso Corporation, the German ZF Friedrichshafen AG and Continental AG, and the Canadian Magna International closes the list of leaders. Ensuring uninterrupted access to scarce components is a key condition for the interest of potential investors in new projects.

The automotive industry is firmly committed to the digital revolution in an industry also known as Industry 4.0, and half of the world's companies are investing more than $ 250 million to modernize their automotive plants.

Thanks to this funding, experts predict that by the middle of the decade, half of the facilities will turn into "smart" factories.

The figures, facts and trends listed above indicate an urgent need to increase funding for high-tech projects for the production of vehicles using flexible, efficient financial models. These options can be modern project finance tools offered by Costex Corporation DBA for large corporate clients around the world.

The current state of the automotive industry in Europe

The automotive industry remains a strategic industry for the European Union, which produces about 19 million cars, vans, trucks and buses a year.Before the pandemic, the EU exported 6 million cars, generating a trade surplus of over € 90 billion and being the largest car exporter in the world.

European car manufacturers had around 300 factories in 26 countries by 2020. They employed more than 13 million people, or 6% of the total available EU workforce.

Funding for the construction and modernization of automotive plants in Europe has steadily increased since 2010, when the European economy recovered from the global economic crisis. This slow growth was interrupted by the pandemic, which set local producers back several years and forced some companies to close underutilized facilities and cut their workforce.

The European auto industry is heavily influenced by the European Commission's debate on reducing carbon dioxide emissions. It is clear that achieving the CO2 emission reduction targets set for passenger cars will largely depend on increased sales of innovative vehicles, including electric, hybrid and natural gas vehicles.

Plans to reduce CO2 emissions and tightening requirements for internal combustion engines are forcing automakers to revise their business development plans and introduce expensive technologies.

This has recently increased the interest of companies in long-term loans for the modernization of automotive plants.

Choosing optimal sources for financing automotive plants

Given the scale of operations, increasing competition and the constant trend towards globalization, external financing plays an important role in the automotive industry.Companies are constantly resorting to bank lending or financing through the issuance of shares and debt obligations.

The capital structure of automotive projects is vital to this business as it greatly influences management and the value of the firm as a whole.

Different automakers choose different debt-to-equity ratios depending on the market niche in which they compete.

In fact, the capital structure depends on the ability of companies to finance themselves with internal resources, on capital requirements and on the volatility of the sector as a whole. The automotive industry has a balanced structure of variable and fixed costs, with high-value assets such as equipment and buildings. However, this comes with extremely high costs, especially when new products are developed and introduced to the market for the first time.

The automotive industry is characterized by low profitability values, which are significantly lower than the average market interest rates. Mandatory payments (interest for the use of borrowed capital at the bank rate and taxes) lead to the fact that the use of borrowed capital negatively affects the return on equity (ROE), which should be used to renew the fixed assets of the automotive industry.

It is impossible to organize high-tech automotive production without adequate sources of capital.

In every enterprise, the selection of suitable funding sources is an important aspect of the business.

The structure of such sources will affect the current financial condition and value of the enterprise.

In the literature, the determinants of capital structure are defined by the so-called perfect and imperfect market theories. One of the main theories of a perfect and efficient market that does not include income tax was formulated by Miller and Modigliani. According to this hypothesis, the average cost of capital of an enterprise does not depend on the capital structure.

The perfect market theories became the basis for the formulation of subsequent theories of capital structure. They serve as the starting point for the vast majority of other areas of the theory of capital structure in the theories of the imperfect market, which finds application in the automotive industry and other areas of modern industry.

According to tax theories, the value of an enterprise increases with an increase in the share of debt in the financial structure.

Firms with a high level of tax shield (including automakers) receive lower tax incentives from financing activities with the involvement of external capital. However, inflationary processes in any case increase the benefits of external financing.

The use of external capital by enterprises contributes to the receipt of benefits in the form of tax incentives on interest, but increases the risks in the form of bankruptcy and agency costs. In general, automakers with high financial risk should limit the use of external sources of financing, and companies with low financial risk should increase their debt until the potential costs of bankruptcy offset the resulting tax breaks.

It is necessary to take into account the innovativeness and high capital costs when organizing new automobile production facilities, expanding and modernizing production lines. Self-financing does not allow most players in the market to solve such capital-intensive tasks against the background of growing global competition.

Professional selection of funding sources

The choice of financing method depends on numerous factors, and it is impossible to clearly determine the optimal level of debt in the financial structure of the project.Much depends on the professional opinion of managers in specific investment conditions.

Experts point out that when choosing a financing structure for automobile enterprises, managers are not always guided by an in-depth analysis of the costs and benefits associated with it. Debt structure is in fact most often driven by biased factors.

The economic units are actually looking for a compromise between maximizing tax incentives and minimizing the costs associated with financial hardship, which will provide an optimal capital structure in terms of company value. Funding assets with fixed capital reduces risk and provides complete financial security, although it leads to an increase in capital costs and a decrease in the rate of return due to the need to maintain an appropriate source.

Financing operations with equity capital is especially important for companies that have problems obtaining loans. In this case, equity capital unambiguously determines development opportunities.

According to European studies, only a few automotive plant managers consider financial activities solely from their own capital to be beneficial for such economic units. The disadvantage of self-financing is the limited ability to purchase high-tech production equipment and modernization due to the lack of sufficient capital.

The factors that determine the choice of the capital structure of automotive plants can be divided into three groups:

• Macroeconomic factors, including economic, legal and political aspects of the automaker. They are independent of the business and because of their influence on the growth of capital expenditures, they should be included in the decision-making process regarding the financing of the enterprise.

• Sectoral factors are mainly due to the variety of market, technological and other factors characteristic of this type of activity. Automakers with a higher share of fixed assets have more negotiating opportunities to raise external capital, while showing less flexibility on the other hand.

• Internal factors should be considered individually, taking into account operational risk, which depends, among other things, on fixed costs, demand volatility, the ability to adjust selling prices in response to changes in factors of production and the ability to develop new products.

Among the main factors that determine the effectiveness of the use of financial capital by automotive enterprises, an important place is occupied by the factor of the state strategy of economic development.

The latter determines the sectoral proportions and trends at the macro level and, contributing to the development of a priority sector, complicates the functioning of others.

Thus, the aggregate of objective factors independent of the automotive industry forms their mechanism for the use and reproduction of financial capital in order to achieve the main goals and areas of activity.

The optimal structure of the financial capital of automotive enterprises means the ratio of the use of own and borrowed funds, which should ensure a harmonious combination of risk and profitability of each project.

When choosing funding sources, company managers are guided by the maximization of value for the owners. Therefore, domestic financial resources should only be used to finance fixed assets. Due to the short duration of participation in economic activities, it is preferable to finance current assets with borrowed funds (primarily bank loans).

Short-term financing is cheaper than long-term financing due to the difference in interest rates. It is also more flexible as the value of short-term liabilities can be decreased / increased depending on the needs of the borrower. The effect of preference for short-term debt financing means a high risk of losing liquidity, which, in turn, can lead to bankruptcy of the company. Moreover, short-term interest rates tend to change more frequently.

On the other hand, sources of long-term debt financing should be used as the main source of current assets, since they allow for the positive effect of financial leverage.

Financing the modernization of an automotive plant through the combined use of internal sources of capital and debt financing usually leads to optimal results.

This allows companies to minimize the risk of losing financial liquidity and reduce the cost of raising capital. Thus, the efficiency of the automotive industry and related industries largely depends on the choice of funding sources.

Project finance for the construction of automotive plants

Project finance (PF) can be defined as the attraction of external financial resources for the implementation of a project with a limited resource base of the initiating companies.This option is ideal for car manufacturers who, for various reasons, cannot obtain a bank loan that requires collateral or unacceptable restrictions for the borrower.

Currently, the PF concept is mainly applicable to large-scale infrastructure, oil and gas and energy projects with the participation of the private and public sectors (PPPs), which have highly leveraged financial structures and rely on careful examination and risk sharing by the parties. Nevertheless, project finance for the construction of automobile plants deserves attention from the point of view of implementing capital-intensive innovation projects or stimulating the automotive industry in the developing countries of the world.

Project finance involves financing a specific economic unit, whereby lenders view the project's cash flows and profits as the primary source of debt service. The assets of a specially created project company (SPV / SPE) serve as collateral for the loan, which reliably isolates the project's debts from the financial balance of the companies that initiate the investment project.

Given the relatively low profitability of the automotive industry in general, project finance is not widespread enough in this sector.

Such projects usually require strong external support, for example, government participation and guarantees in the implementation of strategic projects for the local industry.

Benefits of project finance

Financial experts name such advantages of project finance as the off-balance nature of financing, isolation of the project from the initiating company, plus the possibility of using high financial leverage.As the project goes beyond the balance sheet of the interested company, which means that its creditworthiness remains unchanged (this is not possible with conventional loans). The PF allows the business to maintain its independence by providing the future automobile project with SPV assets and cash flows of the project itself.

The main disadvantage of project finance for the construction of automotive plants is the high hidden cost, which will require the maximum return of projects to service debt through cash flows.

Also, the organization of financing under this scheme requires significant fixed costs for pre-investment research, development, insurance and related services, which is unacceptable for small projects.

Since financing the construction of a new automotive plant today requires investments of the order of several hundred million dollars (depending on the specific volume and model of work), not counting the brand value, the PF looks attractive for projects of this scale for future financial results.

Project finance risk management

Risks are an integral part of project development, and their reduction becomes more relevant to the extent that it will avoid adverse circumstances in the development of the project.For project finance, it is important that all risks are assigned to competent parties who can effectively mitigate them.

PF instruments allow companies to effectively control risks such as political risk, foreign exchange risk, inflation risk, possible growth in prices for raw materials and equipment, legal risks, as well as risks associated with permits and licenses.

For adequate management of the listed aspects, there are mechanisms that can be implemented due to the involvement of several parties to the project. This will help provide the high level of security required by lenders and investors.

Reducing risk is vital when structuring project finance as it leads to greater confidence in the future cash flows of the project company (better known as SPV / SPE). A significant part of the risks is minimized by concluding contracts, while the following contracts are singled out when structuring project finance.

Table: Contract structure of project finance for automobile plants.

| Project contract structure element | Brief description and characteristics |

| Construction contract | Usually the construction of an automobile plant is carried out on the basis of an EPC contract (engineering, procurement and construction). According to this contract, the general contractor is responsible for all the main stages of the turnkey project, including the procurement of equipment and materials, engineering design, obtaining permits, construction and installation. It is essential that the company selected for these contracts has sufficient technical experience not only for the expected quality of the result obtained, but also for meeting the agreed deadlines. It should be remembered that delays and cost overruns negatively affect future cash flows. |

| Management, operation and maintenance (O&M) contracts | These contracts are required after the facilities are put into operation. Sometimes it is important for the initiators of a project that someone controls, operates and performs the appropriate maintenance of the future plant. Such contracts must be entrusted to companies with high technical capabilities, as improper management, operation or maintenance of assets can lead to their failure. |

| Supply contracts | Raw materials and energy supply contracts are necessary to ensure the continuous operation of the automotive plant in the long term. This is usually the case for Take or Pay contracts, but can also be supported by other legal instruments. This type of contract guarantees uninterrupted access to raw materials and energy (for example, the supply of electricity). |

| Sales contracts | Planning for the construction or expansion of automotive production is based on future demand. For capital providers, it may be important to conclude contracts for the sale of future vehicles. Such contracts make it possible to predict future cash flows and ensure their safety. |

Costex Corporation DBA offers contract structure development, consulting and other services for organizing project finance for the construction of automotive plants in European Union, USA, Canada, Australia, Latin America, the Middle East, East Asia and North Africa.

Our finance team is open to your projects, offering professional support anywhere in the world.

Bank loans for the modernization of automotive plants

Adequate capital structure used by automobile manufacturing enterprises determines many aspects of its investment activity and actively influences the final results of this activity.Long-term bank loans are one of the most popular sources of financing for automobile plants.

They are considered a flexible source of capital for businesses, allowing you to customize financial flows and payments depending on the needs of a particular borrower.

The readiness of enterprises to borrow is largely determined by the specifics of the activities of each plant. The size of the plant, the number of years of existence in the market, the level of competitiveness and the need for modernization of production, corporate governance practices, the condition of assets and other factors are important.

Business decisions are based on recommendations from the financial sector and the economy as a whole.

Currently, automotive plants around the world are faced with the need for technical re-equipment and conflicting economic forecasts, which leaves an imprint on the policies of the companies.

Banks “prefer” certain groups of enterprises. This applies to both their size, market share and business structure. Certain industries are characterized by a certain degree of capital intensity.

In manufacturing enterprises, raising physical and financial capital will be significantly different from raising capital in service or commercial enterprises.

Car manufacturers in good financial health are the most credible to lenders because their performance provides ample room for the safe use of external capital for development investment. Strongly positioned companies, whose brand is recognizable among a wide range of clients and investors, have easier access to debt capital.

The role of investment loans in the development of the automotive industry

The priority goal of the development of the automotive industry is to ensure attractive working conditions for participants through the creation of an effective economic mechanism, in which a special place is occupied by credit relations and investment loan.An investment loan is defined as financing of activities aimed at the acquisition, creation, reconstruction, modernization of facilities, as a result of which a stream of income arises that ensures the return of bank funds and payment for the use of these funds in accordance with the principles of lending. Investment loans should help modernize automobile plants, increase asset values, improve quality and structural change.

Investment loan is a long-term loan that is provided to finance investment expenses related to running and developing a business.

This loan is used to finance investment projects related to the reconstruction, modernization or expansion of the company's fixed assets.

The funds received are directed to automotive plants for the expansion or acquisition of new production lines, the purchase of machinery and equipment. The terms of loans are determined through negotiations with the capital provider in accordance with the individual needs of the borrower.

An investment loan can be issued in one tranche or in several tranches in accordance with the schedule for the implementation of a specific investment project.

A key condition for obtaining an investment loan for the modernization of an automotive plant is a documentary substantiation of the project's effectiveness, a complex of financial documentation and a technical description of the project.

To minimize credit risk, many banks require the initiator's own contribution from potential borrowers, which, depending on the size of the project, may amount to 10-20% of the planned investment costs.

Costex Corporation DBA is ready to provide a long-term investment loan for the expansion or modernization of an automotive plant on favorable terms.

We provide a full range of financial services for large businesses.